Afghanistan's New Economic Trend: The Demand for and Opportunities of High-end Industrial Products.

# The Environmental Impact of Pneumatic Conveying Alumina Powder in Afghanistan and Countermeasures

## I. Environmental Impact

- **Dust Emission**: During pneumatic conveying, alumina powder may leak from the pipeline joints or equipment, causing dust pollution. This can affect air quality, harm human health, and cause environmental problems such as soil contamination.

- **Noise Pollution**: The operation of pneumatic conveying equipment generates noise, which may exceed the local noise limits and affect the living environment of surrounding residents.

## II. Countermeasures

- **Equipment Improvement**: Use high-quality, sealed pipelines and fittings to reduce the possibility of alumina powder leakage. Install dust collectors at appropriate locations to capture leaked dust.

- **Regular Maintenance**: Regularly inspect and maintain the pneumatic conveying system to ensure its normal operation. Replace worn parts in time to avoid dust leakage due to equipment failure.

- **Noise Control**: Install mufflers on the equipment to reduce noise. Set up soundproof barriers around the working area to minimize the impact of noise on the surrounding environment.

- **Training and Education**: Provide training for operators to make them familiar with the correct operation procedures and environmental protection requirements. Raise their awareness of environmental protection and encourage them to actively participate in environmental protection measures.

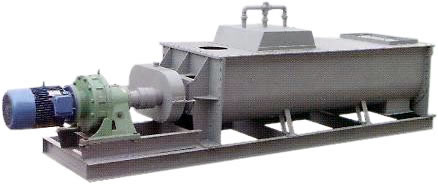

# Energy Consumption analysis and energy-saving strategies of twin-shaft humidifying mixer for alumina powder conveying

## 1. Energy consumption analysis

The twin-shaft humidifying mixer consumes energy mainly in the following aspects when conveying alumina powder. The driving motors of the mixer's two shafts require a certain amount of power to drive the stirring blades, overcoming the resistance during the mixing process. The power consumption depends on factors such as the viscosity of the material being mixed and the rotation speed of the shafts. In addition, the equipment's auxiliary systems, such as the water supply system for humidification, also consume energy. The energy consumption of the water pump is related to the water flow rate and the lift height. Moreover, the transmission system that transmits power from the motor to the stirring shafts has energy losses due to mechanical friction and inefficiency in power transmission.

## 2. Energy-saving strategies

To save energy, several strategies can be adopted. Firstly, optimizing the design of the stirring blades can reduce the resistance during mixing. For example, using more streamlined blade shapes can decrease the energy consumption caused by the movement of materials. Secondly, adopting variable frequency drives for the motors can adjust the rotation speed according to the actual production demand. When the required mixing intensity is low, reducing the speed can significantly save energy. For the water supply system, installing variable flow water pumps can precisely control the water flow rate, avoiding unnecessary energy waste. Additionally, regular maintenance of the equipment, such as lubricating the transmission system and checking the tightness of connections, can improve the efficiency of power transmission and reduce energy losses. Finally, utilizing energy recovery technologies, such as recovering the heat generated during the mixing process, can also contribute to overall energy saving.

Overall improving the environmental management of alumina powder in Afghanistan is an important task that requires optimization of the process flow adoption of advanced equipment and technology strict control of various links and other means To achieve At the same time enhancing the technical content of the twin shaft humidifier mixer is also a key link in the environmental management of alumina powder Only by solving these problems can we truly improve the efficiency of environmental protection transportation of alumina powder and promote industrial development Word of mouth quality is the foundation and promise is the basis Work together with blessings ZHONGYUAN to Afghan customers of twin shaft humidifier mixers We sincerely wish all Afghan customers of alumina powder twin shaft humidifier mixers success in their careers and happiness in their families

Chinese manufacturer - Zhongyuan Innovation Machinery Co. LTD

Email: 18539447368@163.com

Address: Zhengzhou, Henan, China

Tel: +8618539447368

Privacy Policy Allsites Mobile site