Title: Demand for Pakistani Industrial Products Grows: A New Driving Force in Emerging Markets

The demand for Pakistani industrial products is on the rise, becoming a new driving force in emerging markets. With globalization and economic development, Pakistan's industrial sector has made significant progress, and its products are increasingly recognized by international markets. This growth not only boosts Pakistan's economy but also provides more choices and opportunities for consumers in emerging markets.

Pakistani industrial products cover a wide range of fields, including textiles, machinery, chemicals, and electronics. These products meet the diverse needs of emerging markets in terms of quality, price, and functionality. In particular, Pakistani textiles are renowned for their craftsmanship and design, while its machinery and electronics are valued for their reliability and cost-effectiveness.

The growth in demand for Pakistani industrial products is attributed to several factors. Firstly, the improvement of infrastructure and transportation networks has made it easier for Pakistani products to reach international markets. Secondly, the government's support for the industrial sector, including tax incentives and subsidies, has encouraged enterprises to innovate and upgrade. Additionally, the increasing awareness of Pakistani brands among international consumers has enhanced their market competitiveness.

In conclusion, the demand for Pakistani industrial products is growing rapidly in emerging markets, driven by various factors such as improved infrastructure, government support, and brand recognition. This trend will continue to contribute to Pakistan's economic growth and further integrate it into the global market.

The market demand for Pakistani calcium chloride powder has a significant impact on dust-free conveying technology. With the increasing global demand for high-quality calcium chloride, especially in industries such as de-icing and dust control, there is a growing need for efficient and clean handling processes. Dust-free conveying technology ensures that calcium chloride powder can be transported without generating dust, which not only protects the working environment but also improves product quality and safety. This technology helps to meet stringent environmental regulations and enhances the overall efficiency of production and distribution, making it an essential component in the modern calcium chloride supply chain.

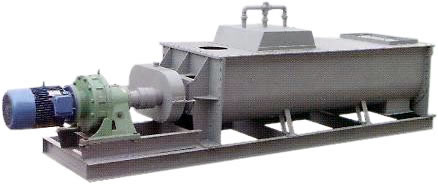

# Optimization Model for Twin-Shaft Humidifying Mixer Parameters Based on Physical Characteristics of Calcium Chloride Powder

## 1. Objective Functions

- **Mixing Efficiency**: Maximize the evenness of calcium chloride powder mixing, ensuring uniform distribution in the mixture. This can be achieved by minimizing the standard deviation of the concentration of calcium chloride in different parts of the mixture. The objective function can be expressed as \(f_1=\frac{1}{n}\sum_{i = 1}^{n}(C_i - \overline{C})^2\), where \(C_i\) is the concentration of calcium chloride at point \(i\), \(\overline{C}\) is the average concentration, and \(n\) is the number of sampling points.

- **Energy Consumption**: Minimize the energy consumption during the mixing process. The energy consumption is related to the rotational speed and operating time of the mixer. The objective function can be written as \(f_2=P \times t\), where \(P\) is the power consumed by the mixer and \(t\) is the mixing time.

## 2. Constraints

- **Rotational Speed**: The rotational speed of the twin-shaft mixer should be within a certain range to ensure proper mixing. Let \(n_{min}\) and \(n_{max}\) be the minimum and maximum allowable rotational speeds, respectively. Then, the constraint is \(n_{min} \leq n \leq n_{max}\).

- **Mixing Time**: There should be an upper limit on the mixing time to avoid over-mixing or excessive energy consumption. Let \(t_{max}\) be the maximum allowable mixing time. The constraint is \(t \leq t_{max}\).

- **Humidity Control**: The humidity of the mixture should be maintained within a specified range to achieve the desired physical properties. Let \(h_{min}\) and \(h_{max}\) be the minimum and maximum allowable humidity levels, respectively. The constraint is \(h_{min} \leq h \leq h_{max}\).

This optimization model aims to find the optimal parameters for the twin-shaft humidifying mixer based on the physical characteristics of calcium chloride powder, considering both mixing efficiency and energy consumption while satisfying various constraints.

In summary Zhongyuan innovation double shaft humidifier mixer with its high-quality products and services has provided strong support for calcium chloride powder related enterprises in Pakistan and even across the country. In the future development Zhongyuan innovation company will continue to adhere to the principle of "valuing contracts and keeping credit" and provide more high-quality and efficient products and services for customers in Pakistan's calcium chloride powder transportation. Braving the wind and waves we embark on a new journey! Working together ZHONGYUAN wishes customers of double shaft humidifier mixers in Pakistan may our cooperation be like fine wine getting better with time and jointly brew a better future.

Chinese manufacturer - Zhongyuan Innovation Machinery Co. LTD

Email: 18539447368@163.com

Address: Zhengzhou, Henan, China

Tel: +8618539447368

Privacy Policy Allsites Mobile site