Malaysia, a country rich in natural resources, has long been known for its limestone deposits. These deposits have significantly contributed to the nation's economy through various industries such as cement production, construction materials, and chemical manufacturing. In recent years, the limestone powder industry in Malaysia has witnessed remarkable advancements, particularly with the adoption of innovative technologies like the twin-shaft humidifying mixer. This article explores how this cutting-edge technology is revolutionizing the limestone powder industry in Malaysia.

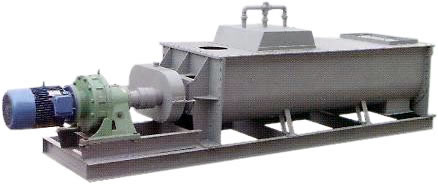

The Twin-Shaft Humidifying Mixer: A Game-Changer

The twin-shaft humidifying mixer is an advanced piece of equipment designed to improve the efficiency and quality of mixing processes in various industries. Unlike traditional single-shaft mixers, the twin-shaft design allows for more thorough and even distribution of materials. Additionally, the humidifying feature ensures that the dust generated during the mixing process is minimized, creating a safer and healthier work environment.

Enhanced Efficiency and Productivity

One of the primary benefits of the twin-shaft humidifying mixer in Malaysia's limestone powder industry is its ability to enhance efficiency and productivity. The twin shafts operate simultaneously but independently, ensuring that all materials are mixed uniformly. This results in a consistent product quality, which is crucial for applications requiring precise specifications, such as in the pharmaceutical and food industries.

Moreover, the mixer's high-speed operation reduces the time required for mixing, thereby increasing overall productivity. This is particularly beneficial for large-scale operations where time is money. By reducing downtime and increasing output, companies can meet market demands more effectively and stay ahead of their competitors.

Environmental Benefits

Environmental sustainability is a growing concern across all industries, including limestone powder production. The twin-shaft humidifying mixer addresses this issue by significantly reducing airborne dust emissions. The humidification process binds dust particles together, preventing them from being released into the atmosphere. This not only improves air quality within the facility but also helps companies comply with stringent environmental regulations.

Additionally, the reduction in dust emissions means fewer health risks for workers. Respiratory issues caused by prolonged exposure to fine dust particles are common in industrial settings. With the twin-shaft humidifying mixer, the work environment becomes much safer, leading to better employee health and reduced absenteeism.

Cost Savings and Longevity

While the initial investment in a twin-shaft humidifying mixer may be higher compared to traditional mixers, the long-term cost savings make it a worthwhile investment. The improved efficiency and productivity translate to lower operational costs over time. Moreover, the durability and reliability of the twin-shaft design mean fewer maintenance requirements and longer equipment lifespan.

Companies can also benefit from reduced energy consumption. The advanced engineering behind the twin-shaft humidifying mixer ensures optimal performance with minimal energy use. This aligns with global efforts to reduce carbon footprints and promote sustainable practices.

Versatility and Adaptability

Another advantage of the twin-shaft humidifying mixer is its versatility. It can handle a wide range of materials, making it suitable for various applications within the limestone powder industry. Whether mixing dry powders or incorporating liquids, the mixer performs exceptionally well. This adaptability allows companies to diversify their product offerings without investing in multiple pieces of equipment.

Conclusion

The integration of the twin-shaft humidifying mixer into Malaysia's limestone powder industry represents a significant leap forward in terms of efficiency, productivity, environmental sustainability, and cost-effectiveness. As companies continue to innovate and adopt advanced technologies, the limestone powder industry in Malaysia is poised for continued growth and success. The twin-shaft humidifying mixer is not just a piece of equipment; it is a transformative force driving positive change across the industry.

Chinese manufacturer - Zhongyuan Innovation Machinery Co. LTD

Email: 18539447368@163.com

Address: Zhengzhou, Henan, China

Tel: +8618539447368

Privacy Policy Allsites Mobile site