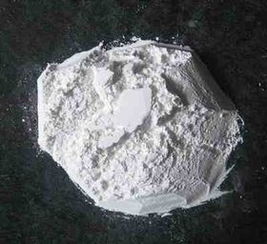

Kaolin, a fine white clay, has been a cornerstone in various industries for centuries. Known for its purity and versatility, kaolin finds applications ranging from ceramics and paper production to pharmaceuticals and cosmetics. In recent years, Lithuania has emerged as a significant player in kaolin processing and exportation. A key factor in this development is the advent and optimization of pneumatic conveying pumps, which have revolutionized the way kaolin is handled and transported within industrial settings.

The Significance of Kaolin in Industry

Kaolin is prized for its bright white color, fine particle size, and chemical stability. These properties make it an essential ingredient in numerous products:

1. Ceramics and Pottery: Kaolin provides the necessary plasticity and whiteness for high-quality ceramics.

2. Paper Industry: It acts as a filler and coating material, improving paper quality and opacity.

3. Paints and Coatings: Kaolin enhances the brightness and durability of paints.

4. Pharmaceuticals and Cosmetics: Its purity makes it suitable for use in medications and beauty products.

5. Rubber and Plastics: As a filler, kaolin improves the mechanical properties and reduces costs.

Lithuania’s rich deposits of kaolin have positioned the country as a vital supplier in the global market, necessitating efficient methods for mining, processing, and transportation.

The Evolution of Pneumatic Conveying Systems

Pneumatic conveying systems have been used for decades to move bulk materials through enclosed pipelines using air pressure. These systems offer several advantages over traditional mechanical conveyors, including:

- Dust-Free Operation: Minimizes environmental impact and health hazards associated with dust exposure.

- Energy Efficiency: Uses less power compared to mechanical systems.

- Versatility: Suitable for a wide range of materials, including powders, granules, and flakes.

- Space Efficiency: Requires less floor space and can be easily integrated into existing infrastructure.

Pneumatic Conveying Pumps in Kaolin Processing

In the context of kaolin processing, pneumatic conveying pumps play a crucial role in ensuring efficiency and maintaining product quality. Here's how they are applied:

1. Mining and Extraction: Post-mining, kaolin is transported from the extraction site to processing plants via pneumatic systems, reducing manual handling and contamination risks.

2. Drying and Classification: After initial processing, kaolin undergoes drying and classification. Pneumatic conveyors efficiently transfer the dried material between different stages of processing.

3. Packaging and Shipping: For export, kaolin must be packaged securely. Pneumatic systems assist in filling bags or containers quickly and cleanly, readying them for shipment.

4. Waste Management: By-products and waste materials are also managed more effectively with pneumatic conveyors, ensuring minimal environmental footprint.

Benefits to Lithuanian Industry

The integration of advanced pneumatic conveying pumps in Lithuania’s kaolin industry has brought about significant benefits:

- Increased Production Capacity: Faster material handling leads to higher throughput and reduced downtime.

- Enhanced Product Quality: Reduced human intervention minimizes contamination, preserving the purity of kaolin.

- Cost Savings: Lower energy consumption and reduced maintenance costs contribute to overall cost efficiency.

- Environmental Compliance: Improved dust control and reduced emissions align with stringent environmental regulations.

Future Prospects

As technology continues to advance, the potential for further innovation in pneumatic conveying systems grows. Smart sensors and automation could lead to even greater efficiencies, predictive maintenance, and real-time monitoring of enhancing operational reliability.

Moreover, with increasing global demand for kaolin and a push towards sustainable practices, Lithuania stands to benefit significantly from continued investment in these technologies. This not only bolsters the local economy but also positions Lithuania as a leader in kaolin production and environmental stewardship.

Conclusion

Harnessing the power of kaolin requires more than just access to resources; it demands innovative solutions for efficient processing and transportation. Pneumatic conveying pumps have proven indispensable in this regard, transforming the kaolin industry in Lithuania. As these technologies evolve, they promise even greater advancements, driving productivity, sustainability, and economic growth for Lithuania and beyond.

Chinese manufacturer - Zhongyuan Innovation Machinery Co. LTD

Email: 18539447368@163.com

Address: Zhengzhou, Henan, China

Tel: +8618539447368

Privacy Policy Allsites Mobile site