Bahrain, a small island nation situated in the Persian Gulf, has long been recognized for its strategic location and transformative economic landscape. In recent years, the country has embarked on an ambitious journey to diversify its economy away from its dependence on oil. A key area of focus within this diversification strategy is the industrial sector, where innovations are being introduced to enhance productivity and efficiency. One such innovation is the adoption of double shaft humidifying mixers for the processing of gypsum powder, a critical material in the production of plasterboard, a staple in construction.

Gypsum powder processing requires precise control over the consistency and moisture content of the material. The traditional methods often relied on simple blending techniques that could result in inconsistencies, affecting the quality of the final product. The introduction of double shaft humidifying mixers has revolutionized this process, offering several advantages over previous technologies.

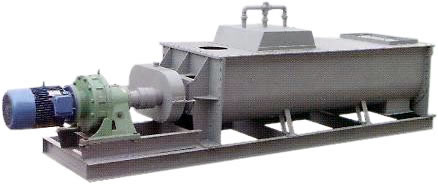

Double shaft humidifying mixers are designed with two counter-rotating shafts equipped with mixing tools that provide a thorough and uniform blending action. This ensures that the gypsum powder is evenly moistened, which is essential for the subsequent stages of plasterboard production.

The humidifying aspect of these mixers allows for precise control over the moisture level. By introducing water vapor directly into the mixer, the equipment can adjust the humidity level of the gypsum powder mixture, ensuring optimal conditions for the formation of plasterboard.

The benefits of utilizing double shaft humidifying mixers extend beyond just the improved blending and moisture control. These mixers also offer higher operational efficiency, as they can process larger quantities of gypsum powder in shorter periods, increasing the overall output of the manufacturing plant. Moreover, the consistent quality of the processed material reduces waste and rework, contributing to cost savings and a more sustainable production process.

In Bahrain, this technological advancement aligns with the country's industrial strategy to promote high-value manufacturing and enhance competitiveness in regional and global markets. By adopting cutting-edge equipment like double shaft humidifying mixers, local industries can not only improve their operational efficiency but also produce higher quality products that meet international standards.

The implementation of such technology also fosters a culture of innovation within the manufacturing sector, encouraging companies to invest in research and development to stay at the forefront of their respective fields. This, in turn, attracts skilled professionals and investors, further strengthening Bahrain's position as an industrial hub.

In conclusion, Bahrain's adoption of double shaft humidifying mixers for gypsum powder processing epitomizes the country's commitment to industrial innovation. As this small island nation continues to push the boundaries of technological advancement, it sets a precedent for other nations in the region, demonstrating that investment in modern, efficient manufacturing techniques is a vital component of a thriving and diverse economy.

Chinese manufacturer - Zhongyuan Innovation Machinery Co. LTD

Email: 18539447368@163.com

Address: Zhengzhou, Henan, China

Tel: +8618539447368

Privacy Policy Allsites Mobile site